Truck Tools Parameters and functions

Disable power and speed limits in the event of an AdBlue system failure

This parameter allows you to disable restrictions on the power and speed of the car in case of failure of components and components that affect the norms of environmental standards.

Perform PCI unit programming.

Pre-injection

Pre-injection is used to reduce noise and improve engine performance.

In some cases, disabling pre-injection allows for more stable engine operation and better efficiency.

To understand why you need it – you need to study physics for 8th grade!

Also read the sharp training documentation!

Water pump

Two-stage clutch coolant pump can operate in two modes At high speed, the coolant pump impeller is driven directly from the crankshaft using a V-ribbed belt. The low speed of the impeller is about 50% of the high speed.

- Impeller

- Static rib

- Speed sensor

- Electromagnet

- Bearing (coupling)

- Friction disc

- Induction plate (aluminum) with built-in metal plates with cooling fins

- Shaft

- Bearing (shaft)

- Permanent magnets

- Pulley without intarder

- Pulley with intarder

- Cartridge body

- Gear

- Rotary seal

Control:

Depending on the cooling requirements of the engine or vehicle, the PCI ECU activates the coolant pump solenoid and changes the impeller speed:

- the electromagnet is on, the pump is running at high speed;

- solenoid off, pump running at low speed.

In the absence of power, the coolant pump’s safe speed is a low speed.

If a two-stage clutch coolant pump stall is detected, a fault is logged and used to disable the EGR system. The PCI closes the EGR valve and reduces the fuel supply to prevent engine damage.

Lambda probe

NOTE:

Starting from week 01 of the 2015 specification, vehicles with MX-13 engines are not equipped with oxygen sensors.

Starting from week 05 of the 2015 specification, vehicles with MX-11 engines are not equipped with oxygen sensors.

EGR valve

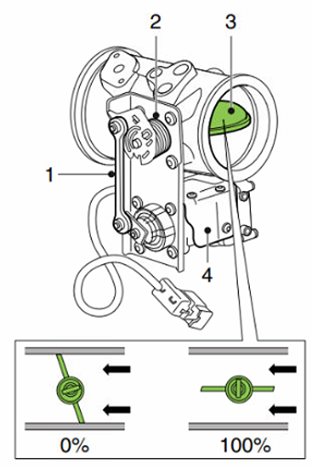

The EGR valve module consists of an EGR valve actuator (2) with a lever (3) and an EGR valve (1).

The main task of the EGR valve is to control the flow of EGR entering the intake manifold. The engine uses exhaust gas recirculation to reduce NOx emissions.

The power-off and fail-safe position of the valve is controlled by a spring, bringing it to the fully closed (0%) position. In the event of a malfunction, the EGR valve moves to the closed position.

In practice, disabling the EGR valve does not affect the system in any way.

BPV valve

The BPV valve consists of an actuator (4) and a BPV valve (3).

The main task of the BPV valve is to create back pressure in the exhaust system and control the exhaust gas mass flow.

After the ignition is turned on, the valve position corresponds to 100% until the PCI ECU starts controlling the actuator.

The power-off and fail-safe position of the valve is controlled by a spring, bringing it to the fully open (100%) position. In the event of a fault, the BPV valve moves to the fail-safe position.

Impact on the system:

- provides heat in the exhaust system necessary to heat the EAS system;

- changing the pressure difference on the turbine rotor to control the turbine with variable geometry;

- creating a back pressure to create a flow of EGR gas;

- creating back pressure to provide engine braking.

Crankcase gas ventilation

Application:

The crankcase ventilation module separates heavier oil particles from the crankcase gases before they enter the environment.

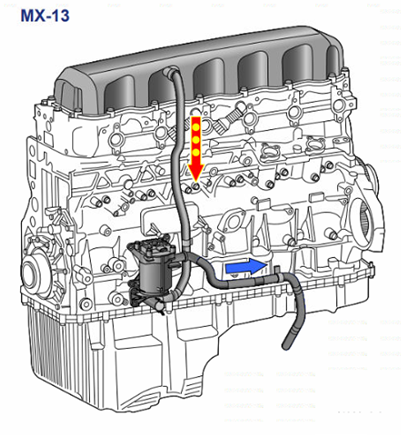

CCV module on the MX-11 engine

Red arrow – introduction of crankcase gases

Blue arrow – the output of purified gas

Yellow arrow – return of separated oil to the oil sump

Switching off the crankcase ventilation module does not affect the engine performance.

Idle timer

Idle stop timer is an additional function that can be set according to legal requirements or at the request of the owner. The PCI ECU may stop the engine after a preset time. This time depends on PTO activation and parking brake activation. The timer will start counting down after all activation conditions are met. The driver will see a message that the engine will stop in the near future due to the event of a stop at idle.

AdBlueOFF Euro6

This function is designed to disable the control of parameters affecting environmental standards.

When using this function, the following conditions must be met:

- use the latest data update for a specific car (download prs update)

- soot level should be standard (not high!)

In the “Main parameters” window, select:

- Humidity sensor (mandatory);

- Lambda probe (depending on the date of manufacture of the vehicle, see “Lambda probe” in this reference manual);

- EGR valve (at your discretion, recommended);

- BPV valve (optional, recommended);

- Ventilation of crankcase gases (recommended);

- Maximum speed (at your discretion, if you plan to change in the future);

- EURO6 AdBlueOff (required);

After selecting the options, click the “Apply” button

Program the PCI & VIC3 blocks (for Europe, we only program PCI).

Remove particulate filter.

Remove the connector from the pump module and the proportioner (in case of disconnection not for Europe)

What is the difference between AdBlueOff and AdBlueOff for Europe???

For Europe, the urea tank level remains operational.